WORKSHOP & EVENTS

WORKSHOPS

SMART MANUFACTURING FOR SMALL AND MEDIUM SIZED MANUFACTURERS

MForesight’s work recognized the enormous potential created by Smart Manufacturing (aka, Industry 4.0) to reshape and restore U.S. manufacturing. Yet surveys have shown that small and medium-sized manufacturers (SMMs) have made little progress in implementing the technology. In consultation with manufacturers, consultants, and technology providers, this project matched technology solutions with specific “pain points” typically encountered on the shop floor of SMMs and provided a practical path forward.

MANUFACTURING HIGH-ENTROPY ALLOYS

DECEMBER 7, 2017 WASHINGTON, DC

High-entropy alloys (HEAs), which consist of five or more elements in roughly equal quantities, gained interest over recent years for their range of unique properties. These advanced alloys have applications in light-weighting, high-temperature environments (e.g. turbines), catalysts, coatings, magnetics, rare-earth replacement, and a range of other areas that require extraordinary material properties or seek to reduce the use of costly elements. HEAs open up a wealth of new opportunities for the United States economy, yet lack an economically viable path to scalable manufacturing.

MANUFACTURING PROSPERITY/GRAND CHALLENGES IN U.S. MANUFACTURING

BOSTON; WASHINGTON, DC; AUSTIN; SAN JOSE; RALEIGH; INDIANAPOLIS; DETROIT

MForesight convened national thought leaders in a series of regional roundtables to conduct a major study on the future of U.S. innovation and manufacturing. This project addressed “grand challenges” for the U.S. manufacturing sector: degradation of the Industrial Commons, offshoring of research and development (R&D), and the dearth of financing for “hardware” start-ups and scale-ups. The report contains actionable recommendations for public and private decision makers to maintain or restore domestic manufacturing capabilities and capture the full value from U.S. R&D investments.

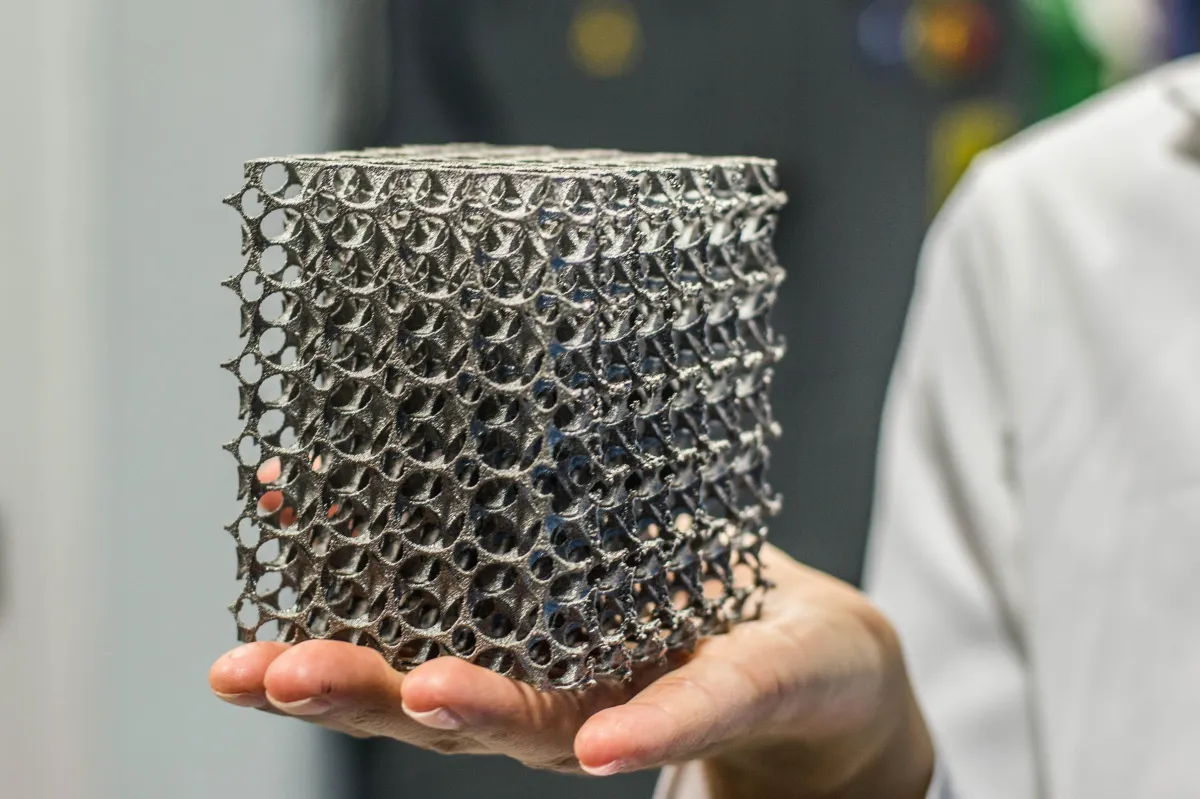

METAMATERIALS MANUFACTURING

Metamaterials can exhibit extraordinary mechanical, acoustic, optical, radio, and surface properties. These materials have the potential to greatly benefit aerospace, defense, medical instrumentation, biomedical, optics, sensing, telecommunication, robotics, and an array of other industry sectors. Many small, lab-scale prototypes have been created using a slow and expensive process; scalable manufacturing has been missing. MForesight hosted a workshop to address this issue.

Annual Summits

MForesight’s work was supported by the National Science Foundation from 2015 to 2020 under Grant No. 1552534 to the University of Michigan (Dr. Sridhar Kota).

Please note that any opinions, findings, and conclusions or recommendations expressed on this website do not necessarily reflect the views of the National Science Foundation or the University of Michigan.